Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

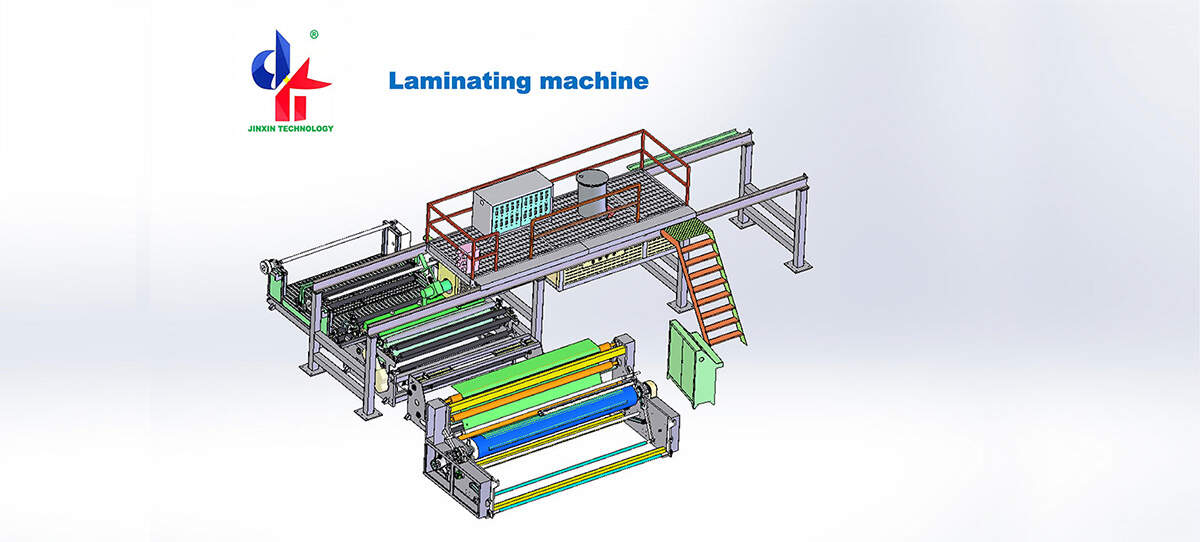

Máquina de laminação e revestimento termofusível de materiais não tecidos para sacos descartáveis para batas cirúrgicas médicas

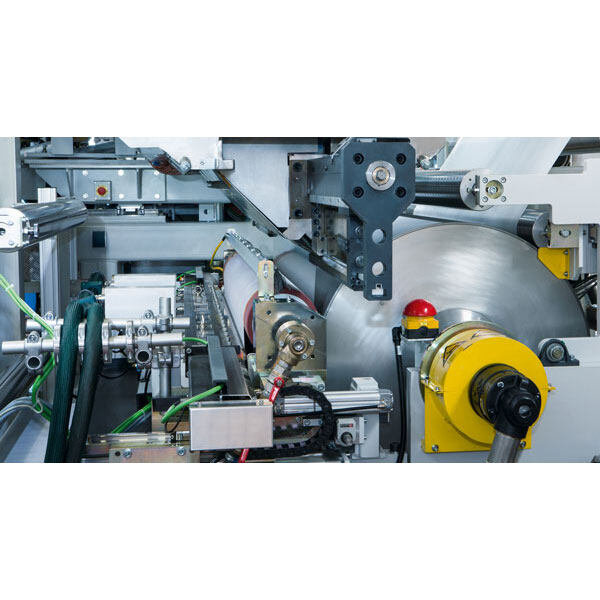

The extruder with helical gear reducer steel adopts an automatic temperature-control system to adjust the melting temperature, and the screw and cylinder are made of alloy steel and have undergone nitrogenation treatment. This nonwoven fabric laminating machine utilizes the excellent adhesive property of polypropylene&polyethylene at melting status to adhere and laminate nonwoven, paper, BOPP, PE, and aluminum foil to nonwoven fabric.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Main Features

1.This Non woven fabric laminating machine makes use of the good adhesive property of polypropylene&polyethylene at melting status machine adheres and aminates Non-woven\Paper\BOPP\PE\Aluminum foil to Nonwoven fabric, the extruder with helical gear reducer steel adopts an automatic temperature-control system to adjust the melting temperature, the screw and cylinder are made of alloy steel and done treatment of nitrogenation.

2.The double-die can do single or double-face coating, the width of coating & laminating can be regulated, and control coating thickness, laminating speed, automatic edge cutting, edge-blowing, cutting-off, and winding devices are applied.

3.This machine has the functions of a fully automatic material receiving and refueling PLC control system, a fully automatic weight control system, and a man-machine operation interface, and it is a high-quality supply in the same industry.

FAQ

1.Q: How long will your engineer reach our factory?

A: Within one week after everything is ready (machine arrival at your factory, nonwoven material, power source, air compressor, etc.All is prepared)

2.Q: How many days will you finish installing?

A: We will finish installation and training within 15 days.

3.Q: What should we charge for your engineer?

A: You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary of 100USD one day per person.

4.Q: How long is your machine's warranty period?

A: All our machines have one year guarantee, starting from the finished installation.

5.Q: How could you do if the parts were broken within warranty?

A: We would express the free replacement parts during the warranty date.

6.Q: Does your engineer understand English?

A: Our engineers understand a little English. All our engineers have more than five years of machine installation experience.

7.Q: How do we solve the machine problem after your engineer leaves?

A: Generally speaking, there will be no problem after finishing the installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according to your description.